THE ULTIMATE MATCH TO BISON INSTINCTS

BISON WORKING WITH US

It is very easy to make bison work for us at round-up time if we give them the opportunity to develop habits that suit our needs while matching their instincts.

Since 1978, I have toured all of America, visiting and studying hundreds of handling systems. I concluded that each ranch had devised its own system, different from the others but with one common feature. All of them pushed or chased bison down long funnel corridors with a mix of horses, tractors, quads, snowmobiles, etc. which is totally contrary to the bison’s natural instinct.

That approach stresses the animal and makes it uncooperative. Often, there are serious injuries and sometimes mortality. I don’t have a monopoly on “bison handling” wisdom. My wish is to introduce an approach based on my observations and my experience with bison behaviour. My basic principle is that a bison naturally wants to go out where it came in.

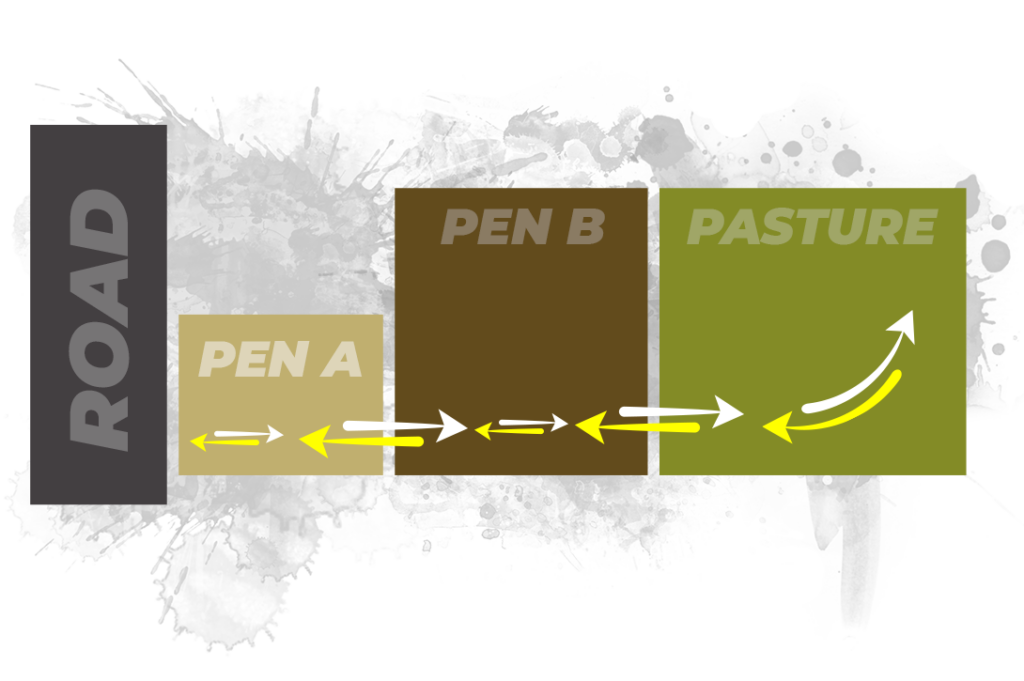

Here’s an anecdote! In 1984, I purchased a lumber contractor’s small herd of 10 bison for $15,000. I thought it would be an easy loading but the seller didn’t agree with me on how to do it. He was asking me the equivalent of reversing the flow of the Mississippi so that it ran towards northern Minnesota, its source. I have drawn the rough outline of the pens he had.

From the pasture, the bison’s habit was to go through pen B to get to pen A for feed and water. To return, they just reversed course. The seller set the transport at the exit of pen A next to the road, a path the bison had never used. For over 3 hours, using as many machines as there were bison, his men tried to force them into the trailer. All to no avail!

I asked him to set the trailer up at the pen B exit leading back to the pasture. We argued at length and eventually, I proposed a “double or nothing” approach. If we couldn’t load them with my setup, I would pay him $30,000. Conversely, if my trailer positioning worked, I paid him nothing for the bison. Two minutes later, the 10 bison were loaded. It was their habitual path! So, I won my point and $15,000. Since then, I’ve saved many $15,000 for ranchers I’ve advised. My belief has often been confirmed: “A bison always seeks to exit where he came in.”

If you want to raise horses you would first build a stable before receiving them. The same goes for chicken, pigs, cows and sheep which means you will build a coop or a barn before your animals arrive. These types of operations have plenty of proven plans and designs available. It should be the same for the person raising bison; unfortunately, this is not the case.

Whatever the size of your ranch, you should have your corral handling facility built before the first bison arrives. Your corral, no matter the size, must have all the amenities required so that bison and workers are safe during the handling process.

You are raising majestic and noble beasts! Your facilities should reflect this. How do you want visitors to your ranch to remember your operation? The corral you build will be a reflection of your respect for your herd.

Here are the main questions you need to answer as you plan your corral:

a) Where will the corral be built?

b) Will it be visible from the road?

c) How is it positioned relative to the sun when in use?

d) Can it be easily accessed from all pastures?

e) Will it have solid, clear access in all weather conditions for transporters?

f) Can you bring water and electricity in easily?

g) Is the location well drained both for bison and for operator comfort?

h) Will it be easy to clean out after use?

i) Is my plan a global one which allows for growth and additions as my herd evolves?

j) How durable will the corral be?

k) Does my proposed corral respect 100% of the requirements of the Code of Practice for the care and handling of bison?

What I am proposing answers YES to all of the above questions.

Your corral will be located in a strategic location not visible from the road to avoid curious onlookers who might misinterpret what they see. In addition, it will be connected to all of your pastures and allow easy access. All types of bison transporters will have problem-free access. Finally, the corral will have a good supply of water (2-inch pipe) and electricity.

The proposed concept corral must have all of the following components without exception. The individual components are identified by a number which links to the attached layout plan for a large 200 breeding-cow herd.

1. Pasture

2. The “Key Stone Alley”

3. Holding pen

4. Waiting pen (in the Key Stone Alley)

5. Gates (in the Key Stone Alley)

6. Deflector (in the Key Stone Alley)

7. Approach corridor

8. Polygon: This structure made of 12 processing sections, can be modified into a horseshoe shape by removing 2 holding sections (8a)

9. Processing sections (between the Polygon and the junction)

10. Junction (at entry to squeeze)

11. Squeeze with scale underneath (11a)

12. Enclosed work office

13. Sorting area (at squeeze exit)

14. Sorting pens after processing

15. Water troughs (servicing 2 pens)

16. Adjustable loading ramp

17. Perimeter corridor

18. Feeding rack for hay, salt and minerals

19. Workspace Alley

20. Gates

With this concept, modules can be added as the herd grows if everything has been planned from the beginning.

If we are to reduce animal stress to a minimum and avoid injuries, we need to pay attention to the following key human behaviours:

l) You must develop bison behaviour know-how. Strive to be a bison whisperer!

m) Always behave calmly

n) Work in silence

o) No smoking

p) Walk slowly

q) Avoid sudden movements

r) Work at same height as the bison

s) Work the bison from one side only

t) No visitors or onlookers

u) Never hit the bison

v) Have a maximum of 5 operators each with a specific task

w) Hold the bison in the squeeze for a maximum of 1 minute

x) Remember that extreme hot or cold weather make it harder for bison to cooperate.

Now we move to the function of each of the corral components. Remember that our purpose is to make the bison “work” for us.

Pasture (no.1), Key Stone Alley area (no.2), holding pens (no.3), small holding areas (no.4), divider gates (no.5), deflector gate in Key Stone Alley (no.6), corridor to processing pens (no.7).

The key to using this corral is the zigzag shaped corridor (no.2) we have called the Key Stone Alley. We need to get the herd used to travelling through it on a regular basis to get to feed and water in the holding pens (no.3).

When it’s “round-up” time, we should eliminate feed from the pasture area (no.1). The bison will travel easily through the Key stone Alley to feed in the holding pens (no.3). They would have used this route for at least a week prior to the round-up so that they are familiar with it.

On the day prior to round-up, we should confine them in groups of approximately 50 in each holding pen (no.3) as they enter. The morning of the round-up, we should close the last door of the Key Stone Alley (no. 5a). We can then release the first holding pen group (no.3) back into the Key Stone Alley (no.2). Once they have travelled the whole length and reached the closed last gate (no.5a), they will turn around, wanting to return to their holding pen (no.3).

This is where we separate them in small groups using the gates (no.5) to create waiting pens (no.4) located in the Key Stone Alley (no.2). At the other end of the Alley, we close the deflector gate (no.6) which directs them into the approach corridor (no.7) leading them into the Polygon structure (no.8) and then into the processing units (no.9).

Polygon (no.8) and straight section (no.9)

The Polygon (no.8) is not required for herds of less than 200 breeding cows. It is made up of 12 processing units and can be reshaped into a horseshoe by removing 2 of the units (no.8a) at the entrance and exit. Alternatively, for a small herd, the whole Polygon (no.8) can be eliminated completely so that the animals can move directly into the straight section (no.9) from the Key Stone Alley (no.2). This requires a realignment of the approach corridor (no.7).

The Polygon (no.8) and the straight section (no.9) contain a series of custom processing units (no.9) that each can hold 5 to 8 bison in a compact grouping. This grouping is less stressful than single file isolation.

Junction (no.10) and Squeeze (no.11) and scale (no.11a)

The last processing section is used to release bison individually into the squeeze (no.11) by way of the junction (no.10). This is a 9 foot-long box with a pivoting side wall to nudge the bison into

the squeeze.

The scale (no.11a) is under the squeeze and its monitor screen should be in the office (no.12). In a well-organized situation the individual bison will not spend more than a minute in the squeeze (no.11).

Work office (no.12)

The work office (no.12) has a door, 2 windows with slide drawers underneath both operated from inside or outside. These allow transfer of syringes, tags, products, etc. without having to enter and exit the office. It should have electricity for heat, lighting, internet, etc. and be located in the workspace alley (no.19) at approximately 10 feet from the squeeze (no.11).

Sorting area (no.13) and sorting pens after processing (no.14)

As the bison exits the squeeze (no.11), it will be in the sorting area (no.13). At this point, you can choose to direct it to one of the sorting pens (no.14) (minimum of 4 sorting pens) or directly back to the pasture (no.1) or directly to loading (no.16).

Water troughs (no.15) and feeding rack for hay, salt or minerals (no.18)

Each holding pen (no.3) and sorting pen (no. 14) has a heated water trough (no. 15) for northern regions. Each trough services 2 pens and each of these pens also has a feed rack (no.18)

Adjustable loading ramp (no.16)

This ramp has to be height adjustable when loading. Corral gates (no.16a) for truck access should be closed when loading. An escaped bison can thus be recaptured.

Perimeter corridor (no.17)

This corridor allows bison to move from pastures to the Key Stone Alley (no.2) so they can then move to the holding pens (no.3). This corridor allows the rancher a travel route to move feed to various pens and to clean up pens. This corridor should be 32 feet wide minimum.

Workspace Alley (no.19)

The Workspace Alley (no.19) is a secure space for workers. All tools are handy.

Gates from one pen to the other (no.20)

Each pen has a latching gate that allows bison movement to the adjoining pen.

All of the elements outlined above are for the benefit of the bison and their handlers. The system is designed to not require the use of force or machines to push bison forward. Instead, it relies on bison developing habits of movement and following their natural instincts.

I hope this article is useful for my fellow ranchers.